Band Saw Blade Sizes

How do you stop a bandsaw drift

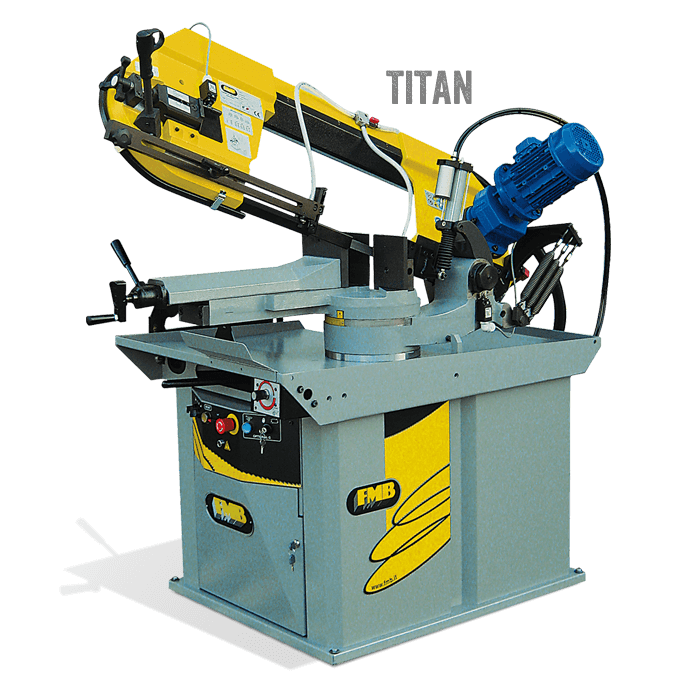

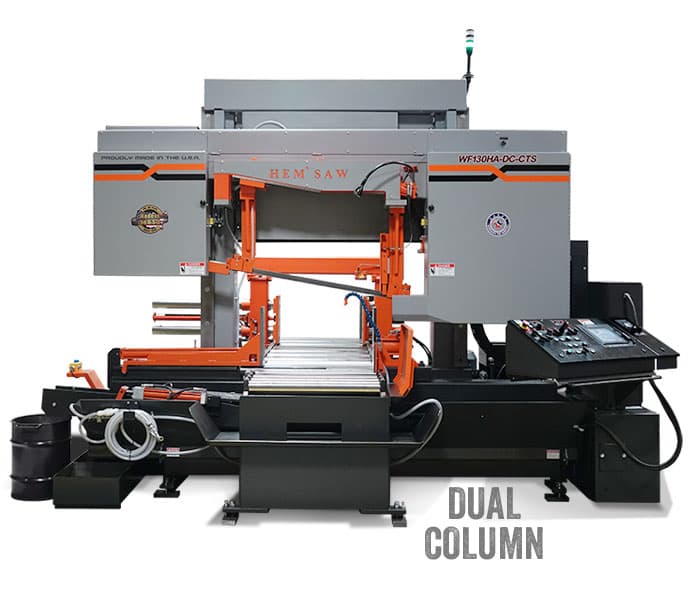

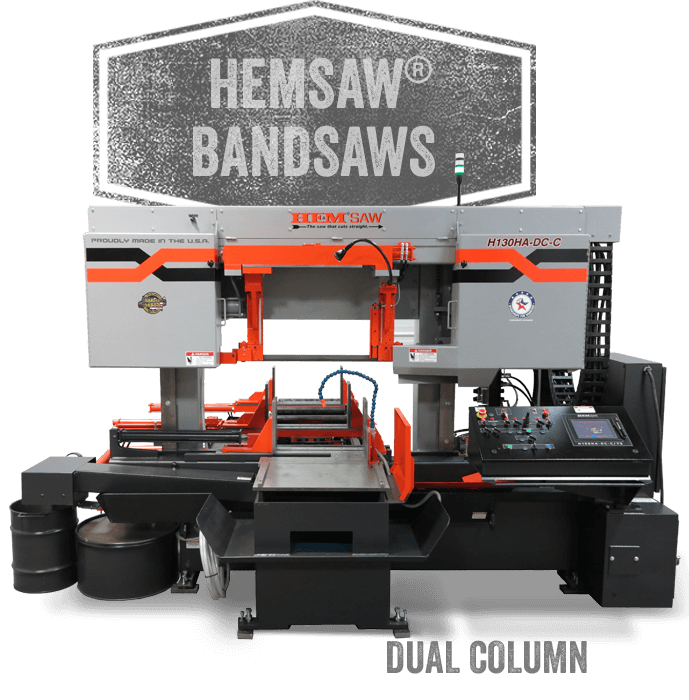

The history and evolution of the band saw dates back a long time. We have many versions of this saw, and there were many before our current model.

They were faced with problems because technology hadn't been developed to create durable, long-lasting blades.

Band Saw Blade Sizes